The Semiconductor Race Enters Deep Waters

The global semiconductor industry has entered a new phase of high-stakes competition. Trade restrictions, material shortages, and export bans have reshaped the landscape. While the United States, Europe, and Japan strengthen their domestic chip supply chains, the world’s attention once again turns to China, following remarks from ASML, the Dutch lithography giant.

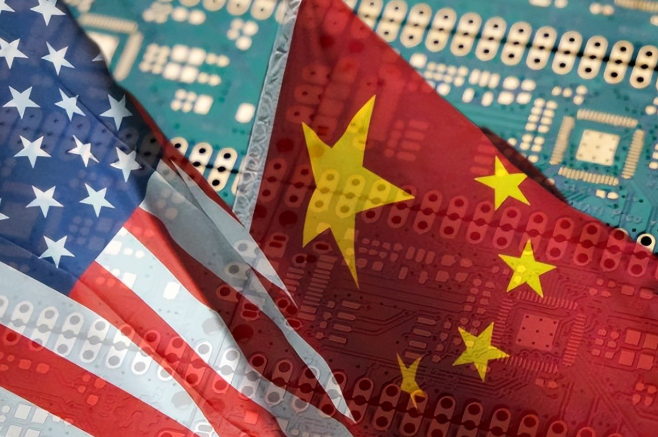

When Western media described the situation as “everyone but China,” it exposed the fragile balance between technological cooperation and geopolitical confrontation. The ongoing battle over lithography machines is no longer just a matter of technology—it’s a contest over global influence.

U.S.-Led Tech Barriers: Turning Sanctions into a Coordinated Strategy

In the past, Washington’s chip restrictions were largely unilateral. Now, the U.S. has formed a coalition with its allies to build a “technological wall” around China.

Since 2018, the United States has imposed tariffs and export bans on Chinese semiconductor firms. The restrictions intensified in 2022 and were expanded again in early and mid-2025, covering not only chipmaking tools but also software, AI training models, and personnel involvement. Even American citizens are prohibited from participating in Chinese semiconductor projects.

Europe followed suit. While criticizing U.S. “unilateralism,” the EU Chips Act allocated €43 billion to support local manufacturers, aiming for “technological sovereignty.” Japan also partnered with Europe in a semiconductor supply chain alert mechanism, which effectively acts as an early-warning system for export controls—allowing governments to monitor sales to China in real time.

Among them, the Netherlands plays a pivotal role. As ASML’s home country, it banned EUV lithography exports to China in 2024 and later added several DUV models to its restricted list. Despite different public justifications, these moves share a common goal: to secure technological dominance and keep China out of the high-end semiconductor ecosystem.

ASML’s Dilemma: Between Law and Market Survival

Caught between U.S. pressure and market reality, ASML faces an impossible balancing act.

As the only company in the world capable of producing EUV lithography systems, ASML should be thriving. Yet, it finds itself constrained by geopolitics. The company’s 2025 Q2 financial report revealed that China now accounts for over 25% of its revenue, making it its fastest-growing market over the past five years.

Despite this, export controls have tied its hands. CEO Peter Wennink (or Christophe Fouquet, depending on the report timing) admitted publicly that ASML “does not wish to be drawn into geopolitical conflicts but must comply with both Dutch and U.S. regulations.”

The company has explored alternative materials and component sources to bypass restrictions, but short-term progress remains limited. With U.S. tariffs already affecting profit forecasts, losing access to the Chinese market could jeopardize ASML’s long-term growth.

China’s Countermove: Using Rare Earths as Leverage and Pushing for Self-Reliance

Rather than retaliate directly, China adopted a dual-track strategy—leveraging its resource advantage while accelerating domestic R&D.

In October 2025, China’s Ministry of Commerce introduced new rare earth export regulations, requiring export licenses for products containing over 0.1% of elements such as samarium or dysprosium, regardless of where they were processed.

Crucially, any materials intended for 14nm or smaller chips, 256-layer memory, or potential military applications now require case-by-case approval—and may be outright denied. Considering that around 75% of key components in U.S. military equipment rely on Chinese rare earths, the move effectively struck at the core of global semiconductor and defense supply chains.

Meanwhile, China intensified its push for technological breakthroughs. In mid-2025, Chinese research teams announced progress on EUV lithography core technologies, unveiling an independently designed prototype. This success wasn’t accidental—it reflected years of strategic focus on building self-reliant, high-end equipment, rather than depending on foreign suppliers.

Like TSMC developing its own photomask systems to reduce reliance on ASML, China’s progress—though gradual—marks a steady path toward technological sovereignty.

A Fragile Balance of Power

Despite the apparent unity of U.S.-led restrictions, cracks are showing. ASML depends on Chinese demand, and the global tech ecosystem still relies heavily on China’s rare earth supply and manufacturing base.

By combining policy leverage with indigenous innovation, China has begun to reshape the terms of competition. The message behind its new approach is clear: no one can be fully excluded from the semiconductor race.

References:

- ASML 2025 Q2 Financial Report

- European Union Chips Act

- China Ministry of Commerce Rare Earth Export Regulation (October 2025)