From Mountain Valleys to High-Tech Foundations

The predecessor of AVIC Optoelectronics was the state-owned Huachuan Electrical Factory, established in the early 1970s in the mountainous area of Yichuan County, Henan. Internally, it was codenamed “Factory 158.” At that time, China was pushing forward the Third Front Construction, and this factory was part of that strategy, mainly producing aviation plugs—basic but critical components.

In its early years, conditions were extremely harsh. Workshops were simple, equipment outdated, and the production pass rate hovered around 60%. Annual output value was less than 300,000 yuan. Workers relied on old Soviet blueprints, laboring during the day and studying improvements at night, slowly raising product quality.

The remote location also meant transportation was a nightmare. Materials had to be carried in from the county seat, and costs were extremely high. Yet in this environment, the factory built the foundation of China’s aviation connector technology, paving the way for self-sufficiency in the aerospace industry.

By the early 1980s, the plant began small-scale production of military components for aircraft and missiles. Output was limited, but reliability improved steadily. Employees meticulously refined processes—from welding to testing—ensuring each part could withstand extreme conditions.

In the mid-to-late 1980s, as reform and opening-up deepened, Third Front enterprises faced market pressures. Huachuan Electrical Factory was no exception: while military orders were stable, it had no foothold in the civilian market. Coastal competitors offered lower prices, and the factory once went three months without paying wages, causing a serious brain drain.

In 1992, leadership made a bold decision to relocate to Luoyang. Staying in the mountains meant at best a few more years of survival; moving out was the only way forward. All employees signed a petition supporting the move. Equipment was transported on handcarts across more than 80 kilometers.

After moving to Luoyang, the factory benefited from proximity to universities, making recruitment far easier. It quickly absorbed fresh talent. Leadership seized the opportunity of “military-to-civilian conversion,” producing telephone connection boxes as civilian products. Though modest at first, these low-tech items opened up new markets.

By the late 1990s, as the telecom industry boomed, the factory’s military-grade fiber optic connector technology came into play. Its performance was 15% higher than imports, and companies like Huawei placed million-level orders. This was a wake-up call: military expertise, when applied to civilian markets, had a crushing advantage.

From then on, the company adjusted its strategy. Civilian revenue grew steadily, reaching 65% by 2002 when the enterprise was restructured and renamed AVIC Optoelectronics. With precision manufacturing as its competitive edge, the company expanded from connectors to optoelectronic modules, broadening applications across industries.

The workforce grew, R&D investments increased, and a complete industrial chain formed. Local resources in Luoyang provided a strong industrial base, ensuring smoother supply chains and avoiding the high costs of coastal regions.

Rising in Luoyang, Conquering the Market

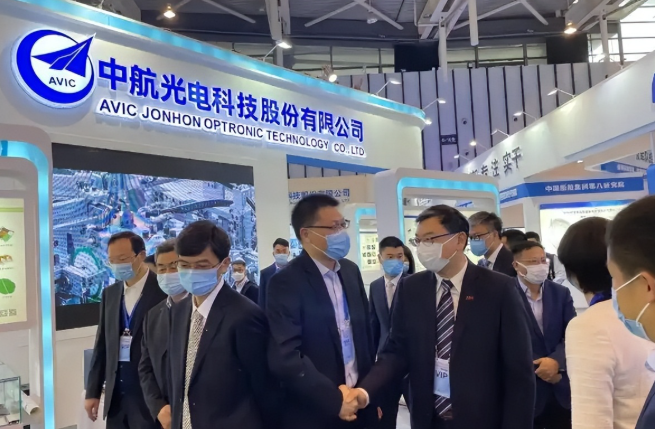

In 2007, AVIC Optoelectronics was listed on the Shenzhen Stock Exchange (stock code: 002179). Few noticed at the time, but it marked the start of rapid growth. Within ten years, revenue skyrocketed from 1.2 billion yuan to over 20 billion, while stock prices surged by more than 800%.

What drove this? Sharp positioning in niche markets. The company captured 75% of China’s aerospace connector market, over 60% of 5G base station optical modules, and even supplied backplane connectors for European and American data centers. Its product lines now span aerospace, telecommunications, and new energy vehicles—low-profile yet highly influential.

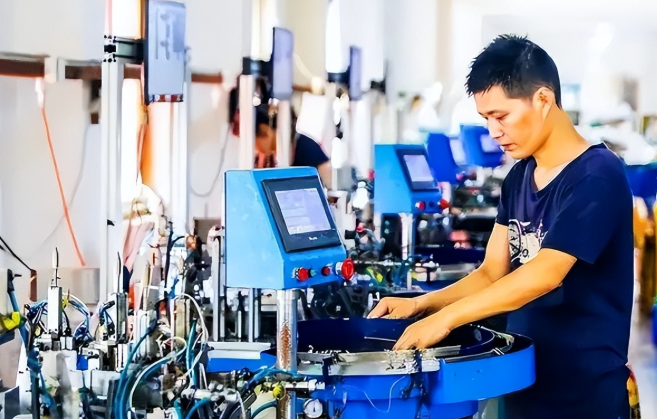

Its Luoyang headquarters is large and modern, with advanced equipment in R&D facilities. Talent is key: in 2015, the company recruited German experts, providing apartments and education support for their families. Today, 42% of its R&D staff hold master’s degrees or higher, including 17 state-subsidized experts.

Even engineers from major cities voluntarily joined, motivated by participation in national projects. The company culture emphasizes both secrecy and innovation. Posters in workshops remind staff of discipline—an atmosphere that sustains technological leadership.

Military-civil integration remains central. AVIC’s components are used in Shenzhou spacecraft and early-warning radar, while in civilian sectors, its products power 5G infrastructure and EV charging guns. During the 5G boom after 2020, orders surged, ensuring steady growth.

Revenue surpassed 20 billion yuan in 2023 and reached 20.69 billion in 2024, with net profits of 3.36 billion yuan. Growth in low-altitude economy and new energy vehicles accelerated, while projects like the European particle collider highlighted its global reach.

For Luoyang, the benefits are immense. AVIC accounts for 15% of the city’s high-tech output, drives over 30 supporting companies, and fosters an industrial cluster. As Henan’s flagship defense enterprise, it boosts jobs and taxes, proving inland cities can excel in advanced technology.

The Military Giant with Unlimited Potential

Today, AVIC Optoelectronics is Henan’s largest defense enterprise. Its headquarters in Luoyang generate annual revenue exceeding 20 billion yuan. Its products support every Chinese space launch, keep 5G networks running, and ensure global data centers operate reliably.

Its military heritage ensures resilience against external pressure. During U.S. sanctions, AVIC’s self-research capabilities filled gaps and avoided technological chokeholds. In the first half of 2025, revenue and profits continued climbing, with stock performance steady.

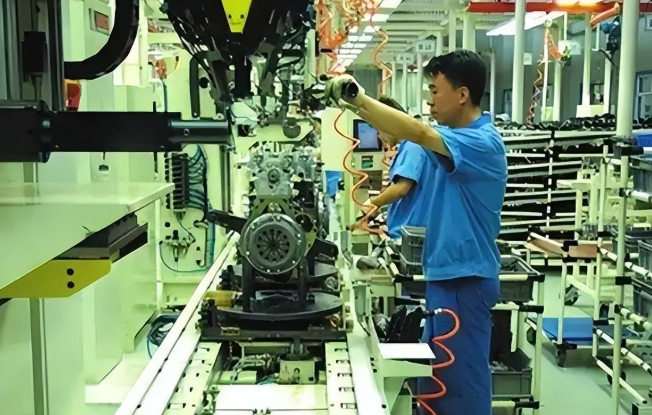

R&D investment remains high, with breakthroughs in 400G optical modules and smart assembly lines doubling efficiency. Talent flows in from Beijing and Shanghai, attracted by high-value projects. A mature local supply chain amplifies impact, creating a strong ecosystem. National policy favors it as a model for military-civil integration, elevating Henan’s role in advanced manufacturing.

The future offers even more opportunities: drones will boost demand for connectors in the low-altitude economy, EV charging systems are expanding rapidly, and overseas markets are growing with Belt and Road projects. Challenges like fast-paced tech iterations remain, but AVIC’s accumulated strength ensures it can adapt.

Defense may sound distant, but AVIC’s products are close to everyday life—your phone signal strength or EV charging speed may already rely on them. With 5G moving toward 6G and space commercialization accelerating, its role will only expand.

For Henan, AVIC Optoelectronics is a source of pride. It shows that true industrial strength comes not from chasing hype but from deep focus on core technologies. As part of China’s broader defense industry, it stands as a powerful symbol of resilience and innovation.

References

- AVIC Optoelectronics financial reports, 2023–2025

- Public statements from Luoyang municipal government on industrial development