In modern transportation infrastructure, the choice of road surface material not only impacts costs but also directly affects safety, comfort, and maintenance difficulty.

China and the United States, two superpowers, have vastly different choices when it comes to road surface materials — the U.S. predominantly uses cement, while China favors asphalt.

Given that both are major countries, why are their material choices so different? Why does China prefer asphalt and avoid large-scale use of cement?

Why Does China Choose Asphalt?

China initially used cement pavement for its highways. In the 1980s to early 1990s, many of China’s highways were built with cement concrete materials.

When these roads were first built, the cement pavement was hard and smooth, providing good initial results for traffic. However, over time, the drawbacks of cement pavement became evident.

While cement pavement is durable on the surface, it lacks sufficient elasticity. When large trucks pass frequently, the pavement develops cracks due to long-term pressure, greatly affecting driving comfort and the road’s longevity.

In contrast, asphalt pavement offers greater flexibility, effectively absorbing vehicle vibrations, reducing noise, and improving driving comfort.

The thermal expansion and contraction of cement concrete is also a significant issue. In regions of China with large temperature differences, especially in summer and winter, cement pavements are prone to cracks.

To address this issue, the road surface had to be cut into smaller sections, forming visible gaps. Even with these measures, cement pavement cannot resist environmental wear and tear, resulting in significant maintenance work.

To overcome the shortcomings of cement pavement, China gradually shifted to asphalt pavement. With advancements in petroleum extraction technology, the production and supply of asphalt increased. By the late 1990s, China’s annual asphalt production soared from 2 million tons to 30 million tons in 2000, making asphalt an ideal material for highway construction.

Asphalt has a relatively higher friction coefficient, especially in dry conditions, where it can reach 0.6, compared to cement pavement, which has a friction coefficient between 0.25 and 0.4.

Even on rainy days, asphalt’s friction coefficient remains above 0.4, greatly enhancing driving safety, particularly in rainy or snowy weather.

The black surface of asphalt pavement also reduces sunlight reflection, enhancing the visibility of traffic markings, making it easier for drivers to identify road conditions.

Asphalt’s flexibility and elasticity allow it to perform better under high pressure and heavy loads. In contrast to cement’s rigidity, asphalt can effectively absorb vibrations from vehicles and reduce noise pollution.

In a highway country like China, driving comfort and noise control are crucial factors.

Asphalt pavement is also relatively simple to maintain. When small cracks appear, new asphalt can be sprayed over the affected area, and the road can typically be restored for use within a few hours.

On the other hand, cement pavement requires a more complex repair process, and once significant damage occurs, the repair cycle is much longer.

Therefore, asphalt pavement has become the dominant material in large-scale highway construction in China, with asphalt roads accounting for 95% of the country’s highways by the end of 2024.

This choice not only makes road maintenance more efficient but also enhances the overall sustainability of China’s highway system.

Why Still Use Cement Pavement?

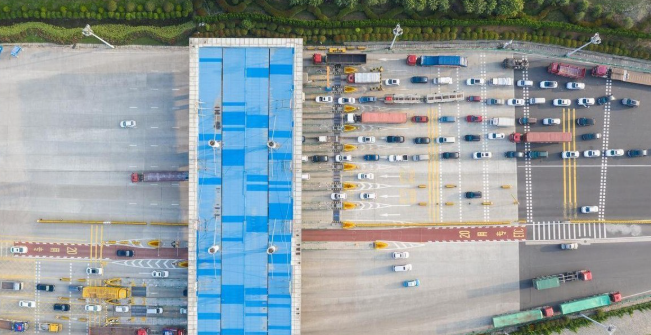

Although asphalt dominates China’s highways, there are still some areas, particularly toll stations, where cement pavement is used.

Why do these areas still retain cement pavement?

One major drawback of asphalt is that it softens in high temperatures. In hot summer weather, asphalt pavement can emit a pungent odor, affecting both workers’ and drivers’ comfort and health.

At toll stations, which experience heavy traffic and long periods of vehicle停over, asphalt pavement is more prone to softening, especially in summer.

Cement pavement, however, is not affected by temperature and can maintain stability even in high temperatures. Therefore, many highway toll stations continue to use cement pavement.

Additionally, toll stations experience heavy traffic, particularly during holidays when vehicle queues are common. In such cases, the load-bearing capacity of the pavement becomes a crucial consideration.

Cement pavement has better compressive strength and can withstand greater traffic pressure. Under these high-load conditions, asphalt pavement may develop severe indentations or damage, while cement pavement can handle the challenge more effectively.

Therefore, cement pavement is still the preferred material in certain toll stations.

Cement pavement is also more durable than asphalt. Typically, cement pavement has a service life of 20 to 40 years, while asphalt pavement lasts around 15 years.

Although the initial construction cost of cement pavement is higher, its longevity reduces the need for frequent repairs and replacements, saving significant maintenance costs in the long term.

Thus, despite asphalt being the mainstream material in China’s highway construction, cement is still chosen for areas with high durability and load-bearing requirements.

Why Does the U.S. Prefer Cement Pavement?

Unlike China, the U.S. has historically favored cement for highway construction, a decision closely tied to its socio-economic background.

In the early 20th century, the U.S. became one of the world’s largest cement producers, and the technology for cement was relatively mature at the time.

Moreover, the funding for highway construction in the U.S. was primarily provided by federal government grants. Cement, being cheaper and quicker to construct, made it the ideal choice.

In the early stages of U.S. highway construction, about 90% of the funding came from the federal government, with the remaining 10% from state governments.

This large-scale government funding helped control the budget, making cement a preferred material due to its lower cost.

As time passed, however, the U.S. gradually transitioned to using more asphalt for highway construction.

Today, only 30% of the interstate highway network in the U.S. still uses cement, and most new highways are constructed with asphalt.

Asphalt is not only more flexible during construction but also adapts better to different climate conditions, lowering long-term maintenance costs.

With global energy demand changes and advancements in asphalt production technology, the U.S. has seen an increasing supply of asphalt, making it the preferred material in many regions.

Conclusion

By comparing the differences in road material choices between China and the U.S., we can see that the decision to use cement or asphalt is not simply a technical issue. It is closely related to each country’s historical background, economic development stage, climate conditions, and traffic needs.

China’s widespread use of asphalt is primarily due to its flexibility, comfort, and ease of repair and maintenance.

In contrast, the U.S. initially chose cement due to its cement production capacity and construction funding constraints.

In the future, with technological advancements and the impact of climate change, the choice between asphalt and cement may become more diversified, especially when addressing the needs of different environments and traffic volumes.

The experiences and lessons from China and the U.S. provide valuable insights and serve as useful references for highway construction in other countries.

References:

- Chinese Highway Construction Report, 2024

- U.S. Federal Highway Construction History, 2020