The shield tunneling machine, essentially an underground “construction pangolin,” first emerged in Europe and has since become an essential tool in global infrastructure projects. The idea dates back to the early 19th century when it was first invented by the British during the industrial revolution, in response to the increasing demand for underground city passages.

In 1825, the shield tunneling machine made its debut during the construction of the Thames Tunnel, where the equipment was basic, like a metal shell, relying on manual pushing to advance, moving only a few meters per week. The inspiration for the shield came from shipworms that drill through wood, using secretions to protect themselves—this principle was adapted to support soil layers and prevent collapse.

By the end of the 19th century, the technology spread to the US and Germany. In the US, shield tunneling played a crucial role in the rapid expansion of subway networks in cities like New York and Chicago. Meanwhile, Germany focused on precision, and the improved version of the shield machine was deployed in the Hamburg Elbe Tunnel, increasing efficiency over the British models.

By the early 20th century, the introduction of electric motors replaced human labor, boosting the efficiency of tunneling. In the 1920s, machines in Chicago could tunnel up to 10 meters per day, and the German Ruhr district mines focused on maintaining high precision, limiting deviation to just a few millimeters.

The 1950s saw the widespread use of hydraulic technology, providing greater stability and adaptability to complex geological conditions. By the 1960s, in Japan’s Tokyo Metro, slurry was injected to stabilize soil, further improving tunneling speeds. With such developments, tunneling projects expanded from city subways to cross-river tunnels, with efficiency increasing from a few meters per week to dozens of meters per day.

In the 1970s, Germany’s Herrenknecht Corporation rose to prominence with the S-880 model, capable of digging 30 meters a day in Munich. The 1980s saw seismic-resistant designs for the San Francisco Bay Area tunnels, and by the 1990s, China began its infrastructure boom, though shield tunneling technology was still largely imported.

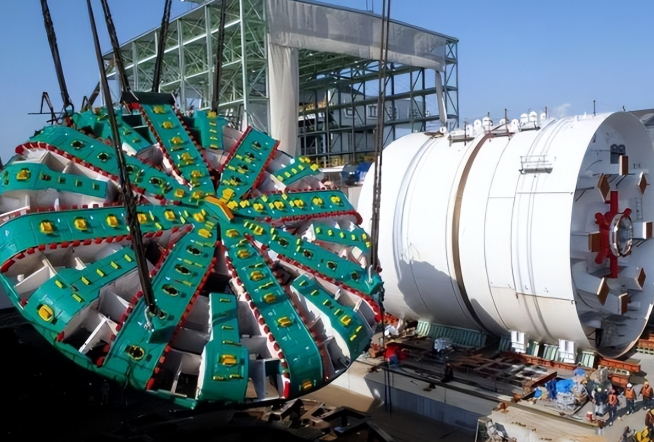

Post-2000: The integration of computer systems and real-time data transmission further revolutionized tunneling, increasing competitiveness in the global market. Machines evolved from rectangular iron frames to circular steel designs, and materials changed from cast iron to high-strength alloys. Cutter heads evolved from simple blades to composite tools, marking a history of progress in engineering technology.

Countries adjusted the use of shield machines based on geological conditions, with hard rocks benefiting from explosive assistance and soft soils relying on slurry balance. Shield machine development wasn’t just about speed but also included systems for safety, dust control, and noise reduction, as global standards gradually unified to ensure compatibility.

Tunneling Machine Speeds and Global Standards:

The core of shield tunneling lies in the speed of digging, which varies based on geology. Early shield machines in the US, such as the Hudson River Tunnel in New York, achieved 2 meters per hour with electric models. In the early 20th century, the Detroit River Tunnel saw 3-meter per hour progress with 5-meter diameter equipment.

The 1940s introduced hydraulic modifications in Los Angeles, resulting in smoother progress, while the 1960s saw the introduction of stainless steel shells for saltwater resistance, with speeds of 3 meters per hour. In 2013, Seattle’s Bertha project, with a 17.5-meter diameter shield, could tunnel 3.6 meters per hour but faced extended maintenance issues due to its large size.

Germany became renowned for precision, starting with manual machines achieving 5 meters per week in the late 19th century and evolving through Herrenknecht’s electric models, achieving 4 meters per hour in Berlin. By the 1970s, their machines reached 6 meters per hour in the Ruhr region. The 1990s saw global exports, with the company becoming known for its low failure rates.

In China, the technology began later, but rapid development followed. In 1997, imported second-hand equipment was used in the Qinling Tunnel, achieving 2-3 meters per hour. By 2008, China had developed its own models, with machines achieving 5-10 meters per hour. In 2019, the “Spring Wind” model broke records with a diameter of 15.8 meters, achieving 10-15 meters per day in soft soils.

2023 Updates and China’s Leading Role:

In 2023, the Hu-Tong Railway’s “Hu-Chi” model achieved 868 meters in a month, averaging 28.9 meters per day. By 2025, the “Chong-Tai Changjiang Navigation” machine will dig 718 meters per month with a 15-meter diameter. In 2024, the “Zhengzhou Downhole” machine will tackle steep gradients and achieve 8-10 meters per day in challenging geological conditions.

China’s shield tunneling machines have become globally competitive, with over 1,700 machines produced, holding a 70% market share. These machines are exported to over 40 countries, demonstrating China’s manufacturing power and technological prowess.

In Conclusion:

From the manual iron frames of the Thames to the intelligent cutter heads of the Yangtze River, shield tunneling machines have seen technological leaps. China’s success in this field reflects the country’s manufacturing strength and competitive edge. As China’s shield machines set records globally, their role in infrastructure development is undeniable, and their technological superiority is evident in the increasingly demanding projects worldwide.